About us

Lab Magnetics has a wide range of R&D, testing and prototyping capabilities available in our facility located in the heart of Silicon Valley in San Jose, California. We provide turnkey engineering solutions, quick-turn fabrication, designing, and testing for all types of magnetic materials and devices.

Lab Magnetics has a wide range of R&D, testing and prototyping capabilities available in our facility located in the heart of Silicon Valley in San Jose, California. We provide turnkey engineering solutions, quick-turn fabrication, designing, and testing for all types of magnetic materials and devices.

Equipped with advanced testing and fabrication equipment, Lab Magnetics serves a multitude of applications across a wide variety of industries including automotive, consumer electronics, appliance, security, medical, sensor, and aerospace. We understand the simple to complex magnetic designs associated with these industries and many others.

At Lab Magnetics, we are passionate about delivering high quality magnetic components and precise analysis of magnetic materials to all of our worldwide customers.

Solutions & Capabilities

Lab Magnetics utilizes in-house capabilities to integrate magnetic functionality into our customers’ products. We provide complete engineering and manufacturing services to work as an extension of your magnetic solutions.

Product Design

Lab Magnetics offers full-service product development capabilities, employing a variety of 2D and 3D magnetic simulation software and characterization equipment. Our engineering team is skilled at material selection and developing complex magnetic assemblies and modules.

Our magnetic capabilities include:

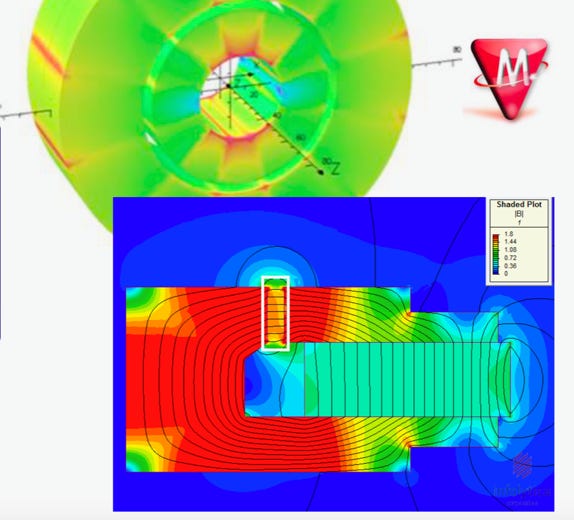

Finite Element Analysis (FEA) is used by our engineering staff to model a design prior to producing prototypes. These modeling programs, including Infolytica MagNet and Ansys Maxwell, analyze magnetic properties in order to arrive at optimal solutions. These solutions can then be tested and fine-tuned against a prototype of the magnet structure or assembly. FEA can also determine flux densities, torque, and forces of a specific design or magnet may be calculated. Results are plotted and analyzed through vector magnetic potentials, flux density maps, and flux patterns.

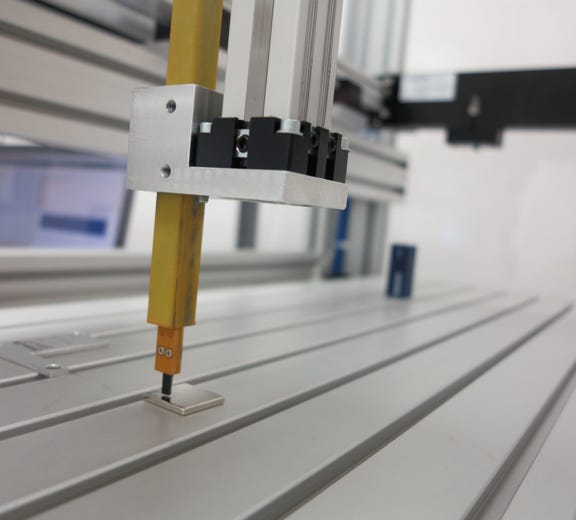

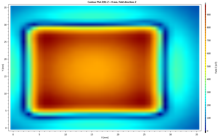

Lab Magnetics uses the GM 460 Brockhaus to obtain 3D measurements of the flux density of magnets and magnetic assemblies. The equipped 3-channel gaussmeter combined with the computer-controlled XYZ movement allows the system to measure and record consistent data. It has the capability of 3 linear movements in the X, Y, Z axes. The XYZ Scanner has a working volume of 400x400x400mm and a step size as low as 0.10mm with and accuracy of ±0.01mm. It can record the direction, amplitude and polarity of the magnets which can be displayed in 3D vector and contour plots.

The Force Measurement System measures the attractive and repulsive force through a range of distances between two magnets, or between a magnet to metal. The system can go as low as Zero Air Gap and determine and record the break away force.

Prototyping

Lab Magnetics’ end-to-end prototyping services provide the flexibility to adjust parameters rapidly and analyze designs more quickly. During prototyping we will work through all stages of the manufacturing process to ensure process optimization. For less complex designs and assemblies, our quick-turn capability can allow for finished prototypes within 48hrs.

Lab Magnetics manufactures all kinds of materials, including NdFeB, SmCo, Alnico, and many other alloys and steels.

Machining

Magnet manufacturing requires special handling, processes, procedures, and equipment due to the brittle nature of materials. Lab Magnetics is equipped with Wire Electric Discharge Machines (EDM), EDM Drill Machines, Linear Surface Grinders and Computer Numerically Controlled (CNC) mills that give us the capability of achieving exact specifications.

Magnetizing

Magnetization is achieved by exposing a magnet or magnetic assembly to an externally applied field. To saturate a magnet, a peak field between 2 and 2.5 times the intrinsic coercivity must be applied. This can be accomplished with the correct magnetizers and fixtures. Our pulse magnetizers generate a field up to 12 T, enabling the magnetization of high coercivity materials, magnetic assemblies, and assemblies with uniquely designed magnetic fields and patterns. Our engineering and production team can offer solutions to the magnetizing process best suited to your applications.

Magnetic Assemblies

Our vast experience with magnetic assemblies spans almost every industry. From micron vibration motors to large dipoles, we understand how to design, manufacture, and use the appropriate fixtures and equipment. Magnetic materials can encounter stress and possible demagnetization which our engineers account for during development of all procedures. Proper assembly techniques and protocols ensures materials are protected, and assembly process is efficient, and the desired magnetic outcome is achieved each time.

Integrate & Testing

Complete magnetic solution testing is available at Lab Magnetics. This includes Magnetic Material Qualification & Validation, Magnetic Field Mapping, Mechanical Force Calculation, Metallic Coating Thickness Analysis, and Soft Magnetic Material Testing. These extensive testing capabilities, combined with our experienced team, make Lab Magnetics a reliable and valuable partner.

Products & Services

Lab Magnetics possesses the latest and most advanced technology and an engineering staff experienced in all magnetic approaches and disciplines. We incorporate elements of Lab Magnetics’ unique information to ensure it adds value to your search.

Resources

This is a real-time calculator for magnetic forces, flux densities, and physical values. Our expert engineer build the tool enabling our customers to design the magnet and draw 2D and 3D models to the most accurate demag curves with Permeance Co-efficient.

© 2024 Lab Magnetics, a Quadrant company. All rights reserved.

1120 Ringwood Ct.

San Jose, CA 95131

OK